Milk debacterizers

Bacteria removal from milk (and whey) allows significant quality improvements of final products. For instance in production processes, in which during the complete processing the milk temperature isn’t raised above 50 °C – as in the production of raw milk cheese for example – a higher product quality can be reached when using a debacterizer.

Undesirable effects, often caused by bacteria are acid fermentation and cheese blowing. Furthermore the reason for a reduced shelf life of soft cheese and soft cheese based products may also be found in the presence of bacteria. Similarly, bacteria removal greatly contributes to longer shelf life of fresh milk and higher quality of whey-derived products such as serum proteins. ANDRITZ Frautech debacterizers represent the optimal solution for bacteria removal – employed with warm milk (ideally at 55-60 °C) for maximum separation efficiency, they guarantee a bacteria removal rate at the highest level.

Features and advantages

- Self-cleaning clarifiers, designed for automated C.I.P.;

- Built-in, manual back pressure control for ease of installation and operation;

- Stainless steel clad base frame;

- High grade finish of any surfaces (wetted and non-wetted parts) for optimum sanitization;

- Optimized motor control for soft start, quick speed recovery after discharge and low energy consumption;

- Innovative lubrication to guarantee optimum working conditions and long life to bearings;

- Time-controlled solids ejections allowing accurate discharges adjustment.

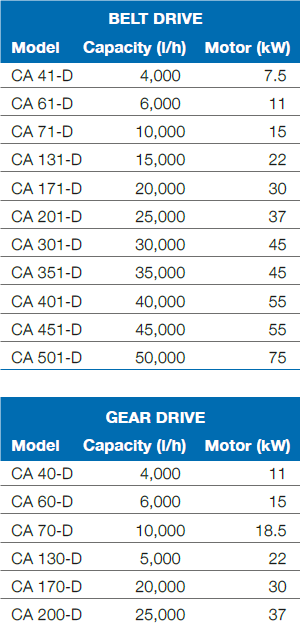

Models and capacities offered