NEW! Cheese processing module

Designed ifor clotting milk, curd cutting and mixing, pressing cheese, whey evacuation:

• done for various types of cheeses: feta cheese, cheese - cheese is no need to obtain a opâritor - fresh cheese;

• module can be designed and dimensioned according to the client's request;

• Heating has two ways: connection to a hot water source (boiler) or by their own electrical resistance.

The equipment is manufactured in accordance with international standards, CE regulations and respecting the newest innovations in the dairy industry.

COMPONENT MODULE

1. The valve mechanized open for cheese - Import Slovenia

• Use: valve is used to perform thermal and mechanical treatments (heating, cooling, maintenance, etc.) required for the processing of cheese. The special permit application of thermal treatment in a temperature range of between 3 ÷ 85 oC. Together with the range of accessories that can deliver these valves can respond to any technological requirements of the user.

• Component: valves are designed and manufactured in accordance with European standards and the latest news in the field of machinery for the dairy industry and has the following important features:

• Stainless steel execution 1.4301 full compliance with all standards requirements for food

• triple walls with polyurethane foam insulation

• heat exchange is done both directly and through the sleeve valve bottom side, which causes a high yield

• heating with an electric resistance system located on the bottom of the valve or hot water circulation between the walls valve (connection to a hot water supply)

• milk is cooling water or chilled water network in a plate heat exchanger. For high capacity valves can be used for water cooling and ice.

• compliance is ensured a very precise set temperatures.

• valve is fitted with three harps cutting.

Component basic equipment:

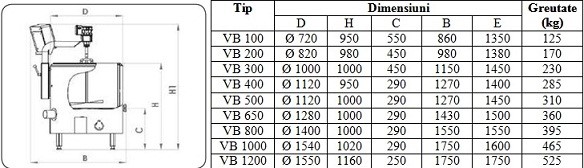

Depending on customer needs, the valve may have different capacities:

2. The valve pressing the curd (variants of classical crinta)

Inner shaft of perforated sheet perforated sheet + caps, for pressing, pressing is done with screws.

Components:

- Outside vana

- Supporting frame

- Stainless steel + rubber wheels

- Liner made of perforated sheet for draining.

- Whey discharge pipe Dn 50

- Pressing caps, with perforations for draining

- Pressing screws

Overall dimensions: 1000mm x 1300 x 800

The valve interior height: 300 mm

3. Centrifugal pump to transfer whey

• model Wilo, Germany

• material: AISI 316

• sealing: the seal IGV

• maximum flow rate: 15,000 l / h

• discharge pressure: 2 bar

• Electric motor: 2.2 kW / 2900rot / min

• Liquid presence sensor for pump protection

• max. Product circulated: 95 ° C

4. Electrical control panel

It is located on the platform and is designed for:

- Frequency converter valve mechanized mixers

- Adjusting the speed of rotation

- Switching the direction of rotation

- Hot water recirculation pump drive

- Whey drain pump drive

- Temperature indication in valve product

5. PLATFORM

It is made of stainless steel and ensure easy access to mechanized and Crinta valve. The platform is equipped with protective railings.

This module is ideal for:

- Farmers

- Small production capacities